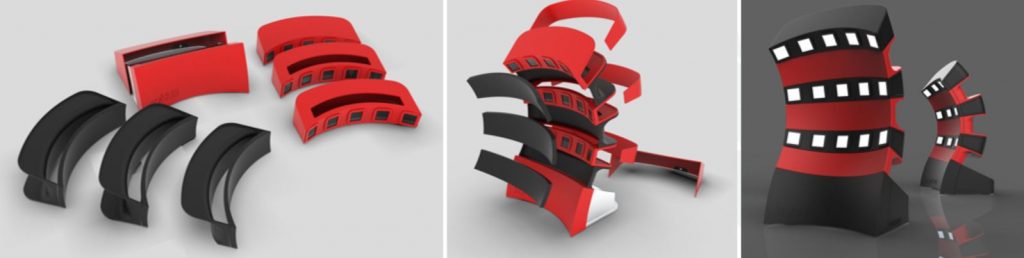

In the FENIX process the jewellery use case will use a custom made 3D scanner in order to scan the human faces and produce highly customised jewellery with recycled precious metals from PCB’s. In order to capture the human face the FENIX team created a prototype scanner which uses 15 cameras and controlled lighting to accurately capture the facial geometry of humans. The prototype design has now been further developed into a detailed design that is more suitable for being a final product ready to be installed in jewellery stores. The detailed design can be seen in the image below:

The detailed design is now being 3D printed and soon all electronics will be assembled in order to make the final assembly ready to be validated.

A second version of the 3D scanner with 9 cameras and a more controlled lighting environment is also being adopted to the jewellery use case. The adaptation of the 3D scanner with 9 cameras will offer better automation in the process of reconstructing the facial geometry and then stitching this together with the jewellery 3D geometry.

#Fenixproject #H2020 #3dscanning #facescanning