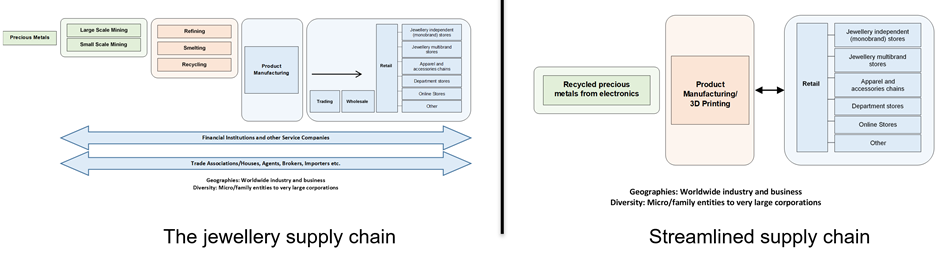

Fenix project is developing a unique process for reintroducing recycled precious metals from waste electronics back to the circular economy in the form of highly personalised and customised jewellery.

The FENIX Jewellery use case has the potential of a total reconfiguration of the channel landscape allowing the jewellers to achieve instant onsite sales with the onsite hardware and the online back end services that will be provided.

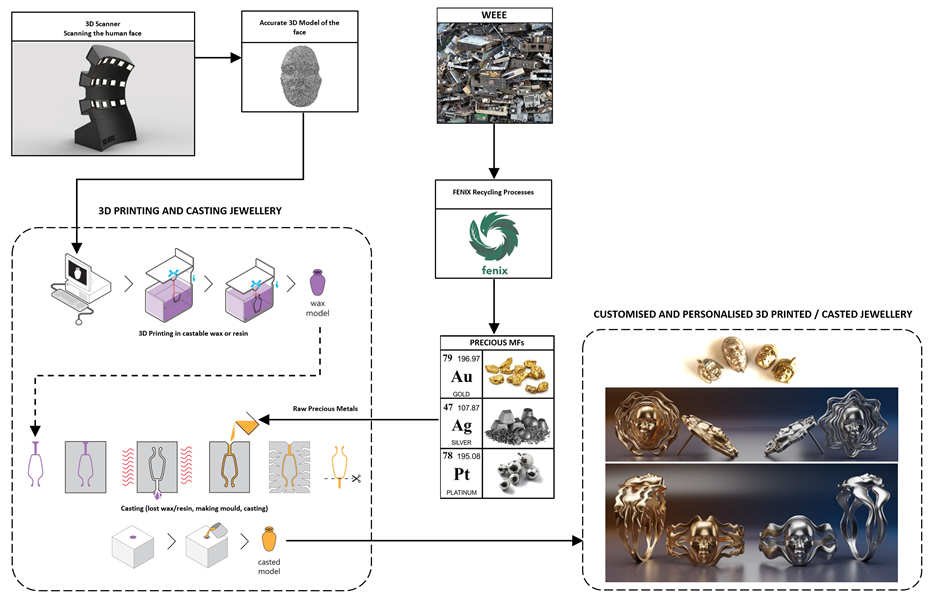

The process which is centred around a Specialised 3D scanner and necessary software with accurate face scanning capability and is installed in direct point of sales (jewellery stores) is described in the image below

The process involves the following steps:

- Clients have the ability to scan their face and through a selection of pre-existing designs order on site a fully personalised and customised piece of jewellery with their 3D facial characteristics

- Custom software processes the order and sends the 3D model directly to the manufacturing site for 3D printing and casting.

- Precious metals recovered by electronic waste recovery processes introduced by FENIX are used in the casting process

- The processed order is shipped directly to the customer or jeweller

Development in FENIX for the specialised 3D scanner is advancing both on the hardware as well as on software level. A photogrammetry-based scanner (The basic principle of photogrammetry is to analyse many photos of a static object taken from different angles in order to reconstruct 3D geometry) has been designed and prototyped

with the following technical specifications:

15 X Raspberry Pi 3

- SoC: Broadcom BCM2837.

- CPU: 4× ARM Cortex-A53, 1.2GHz.

- GPU: Broadcom VideoCore IV.

- RAM: 1GB LPDDR2 (900 MHz)

- Networking: 10/100 Ethernet, 2.4GHz 802.11n wireless.

- Bluetooth: Bluetooth 4.1 Classic, Bluetooth LE

- Storage: microSD.

- GPIO: 40-pin header, populated.

15 X Pi Cameras V2

- Still resolution: 8 Megapixels

- Video modes: 1080p30, 720p60 and 640 × 480p60/90

- Linux integration: V4L2 driver available

- C programming API: OpenMAX IL and others available

- Sensor: Sony IMX219 Sensor resolution: 3280 × 2464 pixels

- Sensor image area: 3.68 x 2.76 mm (4.6 mm diagonal)

- Pixel size: 1.12 µm x 1.12 µm

- Optical size: 1/4″

- Focal length: 3.04 mm

- Horizontal field of view: 62.2 degrees

- Vertical field of view: 48.8 degrees

- Focal ratio (F-Stop): 2.0

15 X Bright Pi

- 1 x Bright Pi PCB (with LED driver chip pre-assembled)

- 4 x bright white LEDs (high quality LEDs)

- 8 x bright IR LEDs (high quality LITEON HSDL-4261 LEDs)

- 1 x right angle header

- 1 x 4 way header cable, 20cm length

- 3 x M2 12mm nylon bolts

- 12 x M2 nylon nuts (to use as spacers as well)

- 3 x stickers

- 1 x info card

Several design choices have been developed and the prototype which has acted as a proof of concept has now been further progressed to a more detailed and refined industrial design that look more like a finished product. Below are the images of the design variant that was the strongest candidate.

A custom firmware to run the 3D scanner hardware has been developed. The firmware is able to provide a GUI to the operator enabling them to:

- Control the lighting by adjusting the luminosity of the led lights.

- Control basic image capture properties (brightness, contrast saturation etc.)

- Fully synchronise the image capture so that all 15 images are captured at the exact same instance.

Custom firmware has been developed using the Delphi programming language (more than 1000 lines of code have been produced to make it work)

Work is ongoing as well on the front end as well as the back-end services that will need to be developed for the whole concept to operate successfully and to also integrate with the remaining FENIX processes.

#Fenixproject #h2020 #3dprinting #3dscanning #jewels